For the application of cold glues, adhesives, lacquers and other cold liquid media.

1 - and/or 2-sided application

Quick-change roller system for flexible application machine use.

Roller change within 5 minutes.

Sturdy design with state-of-the-art motor technology

Essential parts made of V2A

Line or single operation is possible

Applicator roller Ø 240 mm

Drive 1,5 KW -

Servo motor

Speed 5 - 35 m/min

Metering roller Ø 168 mm

Drive 1,5 KW -

Servo motor

Speed 5 - 35 m/min

Back pressure roller Ø 240 mm

Drive 1,5 KW -

Servo motor

Speed 5 - 35 m/min

Working height

850 mm +/-50 mm

Clearance height

1 – 100 mm

Working height adjustment by servo motor

Operation via HMI

Options:

You can use this distribution unit as it is immediately in your production.

Of course, we can also modify the system according to your wishes. This system can become part of a modular system. In our technical centre, we also test your personal task for your economical and fast production.

Just get in touch with us.

Details:

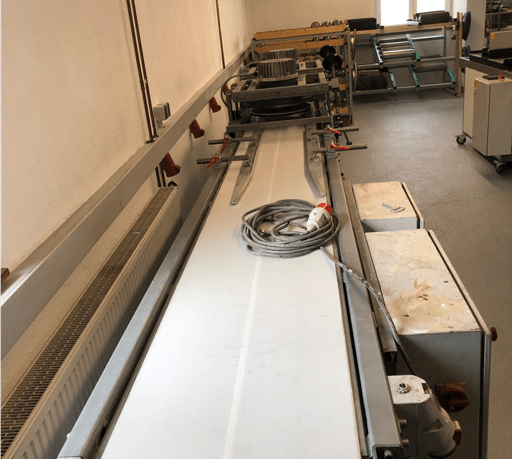

Year of manufacture 2009

Conveyor belt new

1.5 KW belt drive with adjustable speed from 6 to 15 m/min.

Two disc distributors with adjustable speed.

More information about used machines.

High-quality surfaces are best achieved with high-quality materials, qualified employees *and excellent machines.

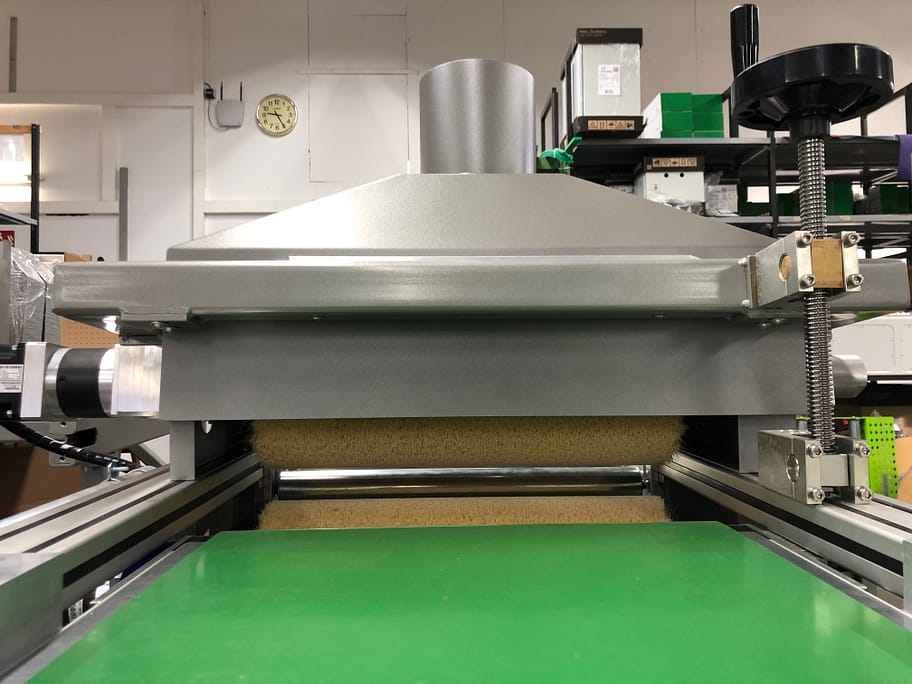

Today we present our double-sided cleaning machine. The mechanical cleaning is done by a driven brush roller at the top and at the bottom. The dust is mechanically loosened by the brushes and then disposed of in the existing extraction system. Thus, the wood is optimally prepared for further processing. For surfaces that dry by oxidation, drying in the lacquer drying trolley is common.

Cleaning on both sides minimises contamination of the coated surface in the lacquer drying trolley, as no more dust can get from the back to the lower freshly coated wood.

The brushes can be changed in a few easy steps.

Speed 3 - 25 m/min

Passage height 1 - 50 mm

Direction of rotation and speed adjustable

Working width 400 mm or 600 mm

This system can become part of a modular system. In our technical centre, we can also test your personal task for your economical and fast production.

Simply get in touch with us.

The stoneware industry is constantly developing in many areas, and machines from Axel Wirth Maschinen GmbH are often used. In order to be able to coat stoneware, you first need the application medium and the right vision, and we will be happy to do the rest for you.

Examples of applications include:

The production of building materials has its challenges. In addition to heavy and hard workpieces, the production environments in stoneware production are completely different from those in furniture production, for example. We have adapted to this and have developed and supplied several solutions for different fields.

Our roller applicators are used Depending on the type of liquid, its viscosity and the desired application weight, we use smooth, grooved or open-pore rollers.

The rubber compounds have to be extremely abrasion-resistant and flexible, which is why we use over 80 different rubber compounds that can also be sandwiched together.

In sandwich construction, we use sponge rubber on the metal core of the roller, which is then covered again with a smooth rubber.

In this way, we achieve a smooth roller surface that is flexible enough to allow good wetting of bevels.

You are welcome to carry out tests with your materials in our technical centre.

Please contact us so that we can arrange an appointment with you in Oberkochen.